Beautiful Plants For Your Interior

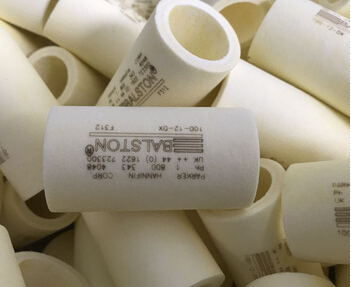

Borosilicate glass fiber sintered filter element Model: B-001

Category: Other products

Product Description

The glass fiber sintered filter element boasts multiple product advantages as follows:

Excellent Filtration Performance

- High-precision Filtration: The filtration accuracy ranges from 0.01μm to 100μm, achieving a filtration efficiency of over 99.99% for fine dust particles of 0.1μm and above. It can effectively remove tiny particulate matter and realize near-zero emission, thus ensuring the purity of the filtered gas or liquid.

- Low Operating Resistance: It inherently features dust repellency, hydrophobicity, and stable chemical properties, with excellent dust stripping performance. Even for highly hygroscopic, easily agglomerated and hardened dust, it can be stripped off effortlessly. This allows the fluid to pass through the filter element more smoothly and reduces operating energy consumption.

Good Tolerance Performance

- High Temperature Resistance: The long-term service temperature can reach 260℃, and the short-term and instantaneous temperature can reach 300℃, with a thermal shrinkage rate of less than 0.5%. It has good thermal stability and high safety in high-temperature environments, and can adapt to high-temperature working conditions such as flue gas dust removal in waste incinerators, cement, chemical industry, smelting and other fields.

- Corrosion Resistance: It can resist the erosion of corrosive chemicals such as acids and alkalis, and can operate stably for a long time under harsh working conditions such as industrial smoke purification with acidic, alkaline and corrosive chemical gases.

Convenient Use and Maintenance

- Simple Structure: With a concise design and no complex internal structure, it is easy for users to understand and operate, reducing the risk of failures caused by complex structures.

- Easy Replacement and Installation: It can be directly matched without changing the shell, and replacing it with this glass fiber sintered filter or filter element can achieve the same level as imported similar products. This greatly saves installation time and cost, and improves the maintenance efficiency of the equipment.

Low Comprehensive Cost

- Low Initial Cost: Compared with some imported similar products, it has a more competitive price. On the premise of achieving the same filtration effect, it can save procurement costs for users.

- Long Service Life: It is fold-resistant, wear-resistant, high in strength, stable in performance and not easy to be damaged, with a long service life. This reduces the labor, material and time costs caused by frequent replacement of filters or filter elements.

Strong Customizability

- Diverse Specifications: The diameter ranges from 10mm to 800mm, and the height ranges from 10mm to 2000mm. Any specification adjustment can be made to meet the diverse needs of different users and different equipment for filter element sizes.

- Customization on Demand: Customized production can be carried out according to customers’ specific needs, such as special requirements for filtration accuracy, shape, material, etc., providing customers with personalized solutions.

Wide Application Range

- Industrial Field: Widely used in the filtration of gases such as automobile engines, natural gas and coal gas, as well as compressed gases such as CNG, LPG and LNG. It is also applicable to flue gas dust removal, oil-gas separation and other processes in industries such as chemical industry, smelting, thermal power plants, product recovery plants, environmental monitoring, clean experiments, instruments and meters, and on-line filters, effectively removing impurities, protecting the normal operation of equipment, and improving production efficiency and product quality.

- Electronic Component Industry: It can provide high-precision filtration guarantee for air purification and gas filtration links in the production process of electronic components, preventing dust and impurities from damaging electronic components, and ensuring the stability of product performance and quality.

- Pneumatic Component Industry: As an ideal product for the pre-stage air source treatment of pneumatic machinery, it can effectively filter impurities, moisture and oil in the air source, provide clean and dry air source for pneumatic components, extend the service life of pneumatic components, and improve the reliability and stability of the pneumatic system.

- Testing Instrument Industry: It is widely used in various testing equipment. Its characteristics of high precision, simple structure, easy replacement and installation enable it to provide stable and reliable sample pretreatment or gas filtration functions for testing instruments, ensuring the accuracy and reliability of test results.

Product Advantages

- High-precision Filtration Performance: Adopting advanced glass fiber sintering technology, it provides filtration accuracy from micron to nanometer level, effectively removing particles, impurities and pollutants.

- High Temperature and Corrosion Resistance: Borosilicate glass fiber material has excellent high-temperature resistance and can work stably in high-temperature, high-pressure and chemically corrosive environments.

- Excellent Chemical Compatibility: Suitable for the filtration of chemically corrosive liquids or gases such as acids, alkalis and solvents, and widely used in chemical industry, petrochemical industry and other fields.

- Long Service Life and High Flow Rate: Borosilicate glass fiber sintered filter element offers a longer service life and lower pressure drop, which can effectively reduce replacement frequency and maintenance costs.

- Uniform Pore Structure: The filtration pores are uniform and precise, ensuring the consistency of filtration effect and the stability of fluid flow rate.

Structural Features

- Structural Stability Ensured by Sintering Process: The sintering process makes the fibers of borosilicate glass fiber material more compact, and the filter element structure more sturdy and durable.

- High Strength and Pressure Resistance: The filter element has high mechanical strength and pressure resistance, suitable for operation in high-pressure environments.

- Wide Temperature Adaptability: It can withstand high-temperature working conditions and adapt to various harsh industrial production environments.

- Pollution-free Design: Adopting a pure design without additives and adhesives, it ensures the pollution-free of the filtration medium, suitable for industries with strict requirements on cleanliness.

Application Fields

- Petrochemical Industry: Used for the precision filtration of fluids such as petroleum refining, oilfield water injection and lubricating oil.

- Chemical Industry: Filtration of chemical solutions and acid-base liquids, effectively removing impurities.

- Pharmaceutical Industry: Filtration of solvents and liquids in the drug production process to ensure the purity and quality of products.

- Food and Beverage: Liquid filtration in food production, such as the removal of solid particles in oils, fruit juices and beverages.

- Electronics Industry: Filtration of high-purity solutions, gases and water to ensure a dust-free environment in the production of electronic components.

Be the first to review “Borosilicate glass fiber sintered filter element Model: B-001”Cancel Reply

Reviews

There are no reviews yet.