Beautiful Plants For Your Interior

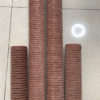

Phenolic resin filter element for oilfield medium flow

The Zilaiquan filter element adopts a unique two-stage filtration design. It can maximize the removal of particulate matter when dealing with viscous substances, organic solvents, and high-temperature fluids, and effectively extend its service life. The outer spiral pre-filter wrapping structure enhances the strength of the filter element and avoids the problem of debris residue commonly found in traditional machined resin-bonded filter elements, ensuring a cleaner filtration process.

The Zilaiquan filter element adopts a non-bonding process and supports production in various specifications. Conventional lengths include 10″, 20″, 30″, 40″, and 50″, and the diameter is 63±1mm (any length within 50 inches can be customized as required). This filter element can provide nine different particle filtration precisions with pore sizes of 1 – 2μm, 5μm, 10μm, 25μm, 50μm, 75μm, 125μm, 150μm, and 200μm to meet the needs of various industrial applications.

Application areas:

• Paint

• Printing ink

• Natural gas

• Adhesive

• Resin

• Latex

• Chemical coatings

• Organic solvents

• Petroleum products

• Process water

• Liquid dyes

• Hydraulic oil

• Paraffin wax

• Plasticizer

• Developer solution

Structural features:

• External spiral wrapping: The outer spiral wrapping helps to collect large particle contaminants, while the inner layer precisely controls and filters particles of the rated size.

• Increased surface area: The external wrapping increases the surface area of the filter element, improves filtration efficiency, effectively eliminates loose debris commonly found in machined products, and reduces the risk of contamination.

• Enhanced strength and fracture resistance: The use of an ultra-long acrylic fiber structure provides greater strength, fracture resistance, and anti-migration properties, avoiding the common problem of particle shedding in the so-called “short fiber” grooved fiber filter elements on the market.

• Customized design: According to the specific needs of users, special ends, plugs, sizes, etc. can be customized to meet different process and environmental requirements.

• Phenolic resin impregnation: The impregnation of phenolic resin enhances the structure of the filter element and is suitable for filtering fluids with a viscosity of up to 15,000 SSU (3200 cks).

• High pressure-bearing capacity: The filter element can withstand pressure fluctuations of up to 150 psid (depending on the fluid temperature), ensuring stable operation under high-pressure conditions.

• Monolithic structure: The monolithic design eliminates the bypass problem of multi-length filter elements, simplifies the replacement process, and improves user convenience.

• Silicon-free structure: The silicon-free structure design ensures zero pollution and avoids negatively affecting the bonding performance of handicrafts such as coatings. The Zilaiquan wound resin-bonded filter element, with its excellent design and outstanding performance, is an ideal choice in the liquid filtration process of various industries, providing users with efficient, stable, and long-lasting filtration solutions.

Reviews

There are no reviews yet.